Who isn’t familiar with the plant with jagged leaves that sting? Stinging nettles grow almost everywhere in the world. Various forms of nettle are amongst the oldest plant crops on the planet. The most prominent is called Ramie, also known as China Grass. In China, it has been grown for 3,000 years. Other nettles used for textile production include the Nilgiri nettle found in the Himalayas, Myanmar and Java and the Siberian hemp nettle (right image), with its long stinging hairs. In Europe, cloth has been made from the Common stinging nettle Urtica dioica (left image) since the Middle Ages. This tensile fibre was used to make sailcloth, rope and clothing. Since the 1990s, the fibres of the fibre nettle Urtica dioica L. convar. fibra have been considered a sustainable raw material by the textile industry. The fibre nettle is a cultivar of Urtica dioica, with a high fibre content. The advantage of growing this cultivar and all types of bast fibre in general is that there is no need for artificial irrigation or fertilizers.

In comparison with animal fibres, nettle fibres are relatively long and thick, with a length of up to 300 mm and a diameter of 40 to 50 microns. But they are quite short if you compare them with flax, with fibres 600 to 800 mm long, or hemp with fibres up to 2 metres in length. The oval to flat fibres are fine and very soft, with a good breaking strength. To obtain the fibre, the stalk of the stinging nettle is cut just above the ground, then broken down after a drying phase. In this way, the woody part of the stem is separated from the bundles of fibre. This can be achieved by hand, or by using mechanical filters, shakers and blowers. The nettle fibre then undergoes further cleaning, with the help of processes using digestive wet chemicals, ultrasound or pressure steaming to remove any remaining bits of wood, bark or dust. At the end of this process the resulting fibre fluff is pressed into a bales and transported to the spinning mill. Here the nettle fibres are processed into roving using carding technology or open-end spinning. This preparation of nettle fibres can create yarns with light, natural beige tones.

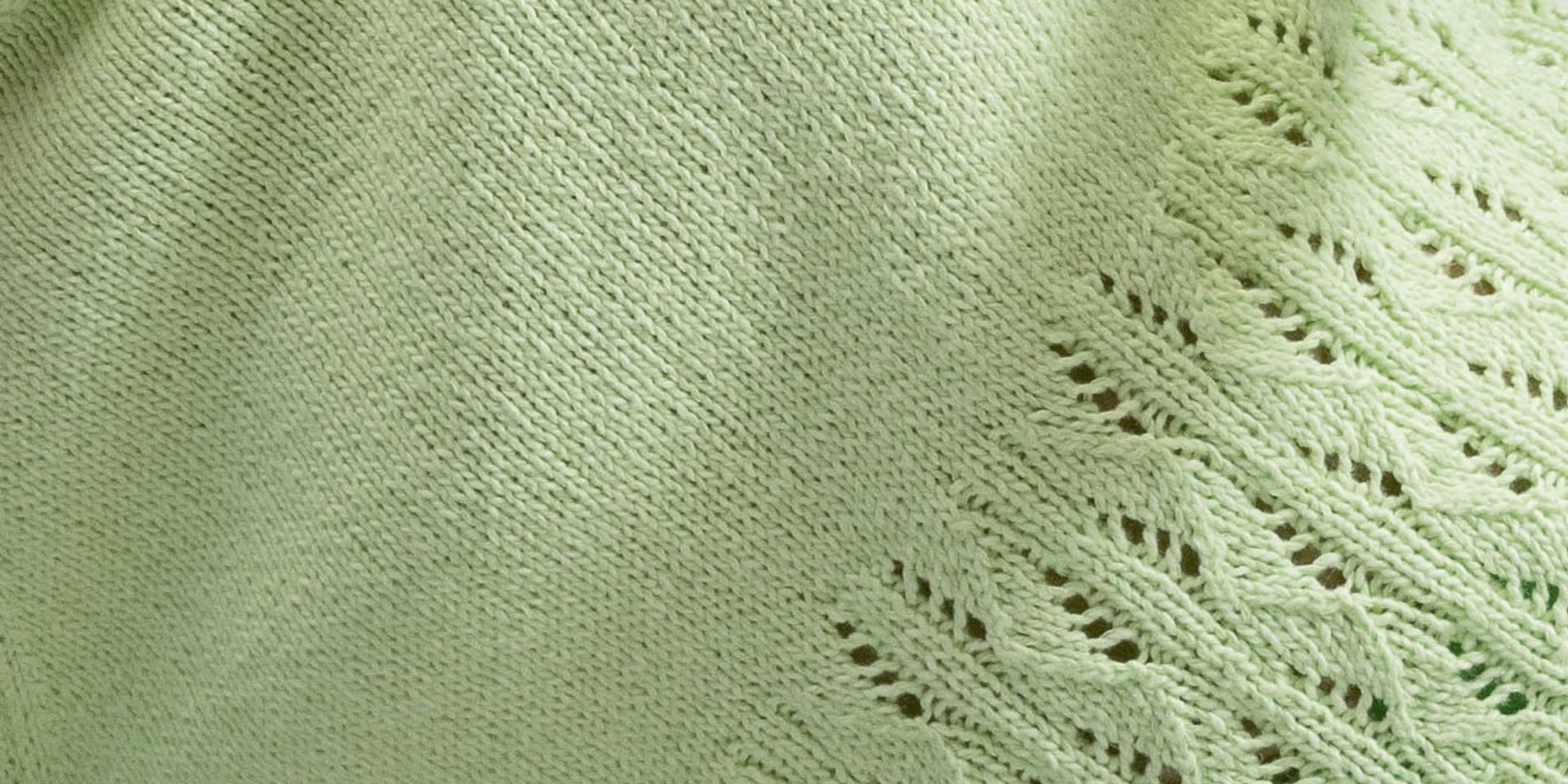

In its spun state the nettle fibre is durable, whilst at the same time being supple and lustrous. Yarns made from nettle fibre have a similar handle to linen. They are also particularly absorbent and breathable. Like hemp fibre, nettle fibre is partly hollow inside and filled with air, which serves to insulate and regulate temperature. Yarns made from nettle fibre will knit as an alternative to cotton. In summer, the fibre is cooling and feels comfortably smooth and soft on the skin. Nettle fibre is often spun together with cotton and other bast fibres, where the function of the nettle fibre is to give the yarn stability, durability and textural interest. Similar to cotton and other bast fibres, nettle fibre also lacks elasticity.

Sources

Materialarchiv 2024, Brennnesselfasern, https://materialarchiv.ch/de/ma:material_1697?type=all&n=Grundlagen, 19. 01. 2024.

Brennnessel-Textil, Verarbeitung, https://www.brennnessel-textil.de/2015/10/textil/, 23.01.2024.

.jpg)

.png)